Sanitary Mixproof Valve with Pneumatic Actuator, IS-C Series

Sizes available: 1 1/2" to 4" (DN40-DN100)

End connection: butt-welded, tri-clamp

Body material: AISI 316L

Seat material: EPDM, FDA177.2600

Max. working pressure: 145psi (10bar)

Min. working pressure: absolute vacuum

Temperature range: 14°F to 266°F (-10 to 130°C)

Operation: pneumatic actuator + C-TOP

Actuator air pressure: 79-102 psi (5.5 bar-7 bar)

Internal treatment: Ra 16 ~ 32µin (0.4 ~ 0.8µm)

Unique design: Judging the seat is broken or not by observing whether the liquid flows out from the bottom of the valve

APPLICATION

SV-5MP-IS series is a completely hygienic double sealing mix-proof valve. This system allows for the simultaneous processes in the two bodies of the valve by providing interface between the two fluids, preventing the possibility of product contamination, the leakage chamber and leakage detector can be self-cleaned through seat lifting. The mixproof valve is applied to food-processing industries, especially in the beverage and diary industries.

OPERATING PRINCIPLES

● Lift type mixing proof valve is remotely operated by compressed air. It is normally closed before running.

● The mixing proof valve is constructed with two independent plugs, which will form a leakage chamber to atmosphere under normal working status. When occasional failure causes leakage happen, medium will flow into the chamber and be diacharged at the outlet port.

● The leakage chamber is closed when the valve is operating, the medium can flow through one pipeline to another. This valve can be clean in place. Many options of CIP and SIP combination are available to users.(Refer to cleaning sterilization function options)

● Clean system can clean the upper, lower stem and leakage chamber, which ensure the valve to be high hygienic. Effectively cleanig system makes the fluid that special for (CIP) clean in place directly wash all the inside calve body, it takes shorter time than common cleaning system.

● Another beneficial of the high cleaning system is that the lift type mixing proof valve can be applied to aseptic processing. If user’s steam into CIP pipeline, the system will constitute a shield that can isolate air.

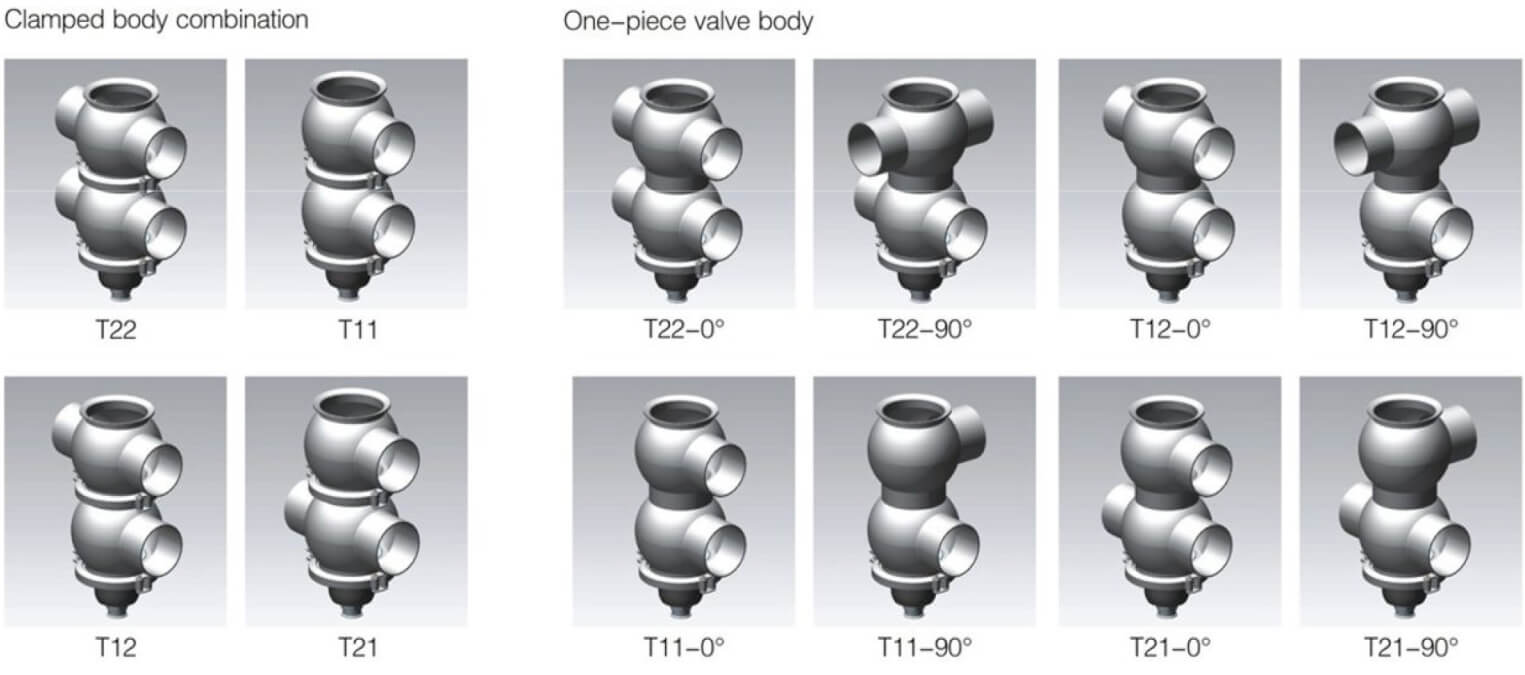

FLEXIBLE BODY COMBINATIONS

TECHNICAL DATA

| Product wetted parts | AISI 316L |

| Other stainless steel parts | AISI 304 |

| Seat Material (Default) | EPDM, FDA177.2600 |

| Seat Material (Option) | FPM (Viton), FDA177.2600 |

| End Connections | butt-welded, tri-clamp |

| Max. Working Pressure | 145psi (10bar) |

| Min. working pressure | absolute vacuum |

| Working Temperature | 14°F to 266°F (-10 to 130°C), 284°F (140°C) for short time sterilisation. |

| Internal Finish | Ra 32μin (0.8μm) as default, Ra 16μin (0.4μm) as best. |

| External Finish | sandblast, or others upon request. |

| Pneumatic Actuator Types | Normally Closed (NC) – Air to open and spring to close; Normally Open (NO) – Air to close and spring to open; Air to Air (AA) – Air to open, air to close. |

| Actuator air pressure | 79-102 psi (5.5 bar-7 bar) |

| Units for intelligent control and indication | C-top control IL-top control (Positioner) Electric connection AS-I bus connection |

DESIGN FEATURES

Design Features

● Default with normally closed pneumatic actuator

● Compact and robust design, forged spherical bodies

● Pressure balanced design

● One-piece Body & Clamped Body for choose from

● A wide selection of different body combinations.

● Easy disassembly by releasing the clamp

● Cleaning/Sterilization Parts for Options

● 100% hydraulic tested / 100% inspected

Operations

● Actuators

Stainless steel actuator

● Units for intelligent control and indication:

C-top control

IL-top control (Positioner)

Electric connection

AS-I bus connection