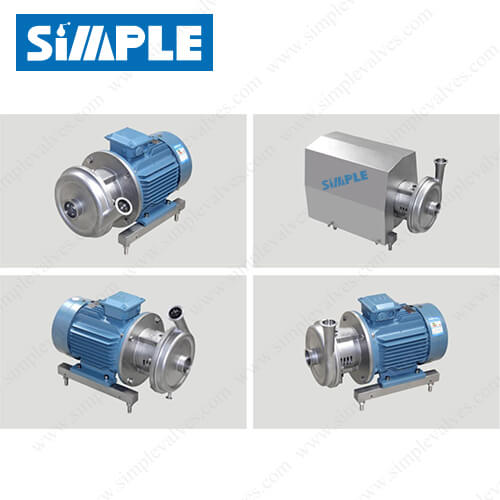

Sanitary Self Priming Pump, CIP Pump

Inlet & Outlet Sizes: 1 1/2"-3" (DN40-DN80)

End connections: butt-weld, tri-clamp, thread, flange

Body Material: AISI 304 (1.4301), AISI 316L (1.4404)

Mechanical Seal: SIC/SIC/EPDM, C/SIC/EPDM

Power Supply: 0.75KW-15KW

Voltage: AC110V, 220-240V, 360-400V, 420-460V, 630-690V, 50/60Hz

Maximum Flow Rate: 30m³/h, 132GPM

Maximum lift: 30M-70M

Maximum Pressure: 43psi, 3bar

Maximum temperature: 120℃/248°F

Maximum rotating speed: 1750min-1

Maximum suction head: 8m/22ft

Surface treatment: Ra 16 ~ 32µin (0.4 ~ 0.8µm), Ra 32µin as default.

APPLICATION

SV-18C series Sanitary Self Priming Pump is specially designed for pumping materials that containing air or gas, and it can also be used for negative suction with prior priming as well as with filtration equipment.

It can be used for wine, oil, syrups, volatile products, such as alcohol, acetone and other solvents,or with products at temperatures close to boiling point. However, the main use of this pump is for CIP recover and suitable for food-processing, pharmaceutical and chemical industries.

TECHNICAL DATA

| Inlet & Outlet Sizes | 1 1/2″-3″ (DN40-DN80) |

| End Connections | butt-weld, tri-clamp, thread, flange |

| Body Material | AISI 304 (1.4301), AISI 316L (1.4404) |

| Mechanisal Seal | SIC/SIC/EPDM, C/SIC/EPDM |

| Power Supply | 0.75KW-15KW |

| Voltage | AC110V, 220-240V, 360-400V, 420-460V, 630-690V, 50/60Hz |

| Maximum Flow Rate | 30m³/h, 132GPM |

| Maximum lift | 30M-70M |

| Maximum Pressure | 43psi, 3bar |

| Maximum temperature | 120℃/248°F |

| Maximum rotating speed | 1750min-1 |

| Maximum suciton head | 8m/22ft |

| Internal Finish | Ra 16 ~ 32µin (0.4 ~ 0.8µm), Ra 32µin as default. |

| External Finish | Ra 16 ~ 32µin (0.4 ~ 0.8µm), Ra 32µin as default. |

DESIGN FEATURES

● High Purity, Low Noise

● Motor cover manufactured with cold-formed plate

● Stainless steel investment casting inlet body and impeller

● Mechanical seal prevents contacting between the spring and the pumped fluid

● Stainless steel support

● Hygienic designed according to 3A standard

●Sanitary mechanical seal, easy cleaning and maintenance

● Gentle material handling without damage

● Motor utilize the IEC EN IE2, PTC thermistor.