The sanitary sample valves are used in industrial processes that require representative portions of fluids (liquid, gases, powder, slurries or fluidized solids) to be obtained from a tank or pipeline for some examination – either physical or chemical analysis.

By enabling the extraction of samples from any section of the pipelines or reactors, sanitary sample valves facilitate a range of industrial processes such as:

- Regulatory assessment

- Quality control

- Analysis and Identification of fluid properties.

Advantages of Sanitary Sample Valves

Sample valves have enabled the testing and analysis for microbes and physiochemical toxins in various manufacturing plants. The advantages of sample valves are:

Sanitary sample valves feature reliable leakproof sealing that eliminates exposure to fumes and liquid drops, which would otherwise lead to skin burns, inhalation of toxic fumes or reactions & explosions.

Sanitary sample valves feature minimalistic design and very few features that are easy to handle, operate, and maintain clean. They can be fitted to take portions from anywhere along the pipeline or processing plant.

Sanitary sample valves are engineered to exacting tolerance with precise and excellent throttling that enables the use of the right dosages in various analytical works. This high standard feature ensures that the results from sampling activities are accurate.

They are designed to enable the taking of millions of samples from high-pressure vacuum operations and extreme temperature systems. Sanitary sample valves can survive from the toughest sanitary operations out there.

Sanitary Sample Valves Classification

Sanitary sample valves are available in a variety of configurations, mode of operation, valve seat, body shape, and end connections. Here are the broad categories of sampling valves you are likely to find in the hardware store near you:

Aseptic Sampling Valve

For anything to be deemed aseptic, it must be free of contamination from bacteria and other microorganism activities. Valves that are considered aseptic feature no-residue bodies, polished clean surfaces, and unique designs that allow for inspection and easy cleaning.

The Aseptic sampling valves achieve this as they are designed for easier sterilization before and after fluid portions are obtained. This prevents any bacterial activity inside the valve’s parts. Aseptic sampling valves are available in modular designs so you can configure them according to your sampling requirements.

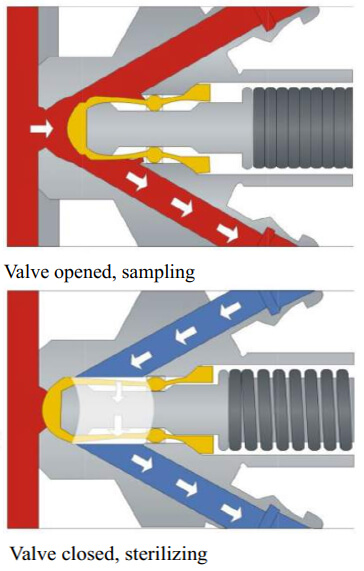

- Opening the valve

The valve is opened by simply manipulating a handle or activating an ON/OFF lever on the valve. Manipulation is either manually or pneumatically done. In manual operation, the handle is rotated anti-clockwise to retract the stem and diaphragm from the O ring seat.

- Closed to sterilizing

There’s an in-built spring that helps to close the valve, and it also keeps the channel between the hoses accessible for sterilization. Sterilization can be done using steam ionized radiation, steam, dry heat, and gas. When using steam to sterilize, it is safe to install some pressure relief valve on the Aseptic sampling valve’s outlet.

Standard Sampling Valve

The valve features a shaft and seal that are maneuvered using a hand wheel, into some up and down motion that opens or closes the valve.

To open the valve, the hand wheel is turned anti-clockwise to lift the seal and shaft off the outlet.

To close the valve, a clockwise manoeuvre is used to move the seal and shaft to the outlet.

Sanitary Sample Valves Materials and Technical Specifications

Based on the conditions you want to do your sampling in, sanitary sample valves are available in an assortment of finishing and trim configurations to facilitate your requirements.

The four most important parts of sampling valves include the valve’s body, the membrane, the spring, and the valves head. The rubber membrane is placed on the valve’s stem either as a dynamic packing in the valve seat to absorb some of the shocks and reduce vibration or a static packing to seal the valve and keep things hygienic by eliminating dead spaces.

They feature AISI304 and AISI316L forged steel bodies, but you can also find some that are designed with FDA approved PTFE technology for reliable sealing and easier in-place cleanability in line with aseptic and hygienic requirements. The forged design also eliminates any welding requirements that would otherwise form dirt-accumulating crevices.

The valve’s inner parts are polished to a fineness of 0.4-0.8μm to enable absolute sterilization even when the valve is in a closed state.

The end connections can be threads, butt-weld, or tri-clamp to enhance the leak-proof sealing property that keeps the portions in the valve away from the external environment for high-quality sample results.

For the seal, PTFE Teflon is used, which makes the valve suitable for use in extreme temperature manufacturing plants.

Most sanitary sample valves can withstand -10°C to 120°C and working pressure of 145 psi / 10 bars. They can, therefore, get fitted anywhere on the pipeline or reactor easily to allow for the taking of fluid portions from any section of the processing plant. When fitted at the bottom of the tank, they help to drain the reside away too.

Application Areas of Sanitary Sample Valves

They are used in various hygienic processes such as biopharmaceutical, food & beverage, and personal care industries. They facilitate reliable, highly accurate, and cost-effective sampling that can be easily reproduced in case verifications are required.

For example, do you ever think of how the drinks you love binging on are made safe? If it were not for the cleverly engineered sampling valves, technicians would have a hard time analyzing the purity of drinks, and your favorite bottle of soda would contain some very dangerous toxins.

In soft drink manufacturing plants, sanitary sample valves are used by technicians to analyze the purity of the water used in the process. Samples are obtained from the chlorine removal towers, and piping then analyzed for microbes or physiochemical toxins. That way, the drink that you finally buy from your local canteens is suitable for drinking.

Our People Want to Help

As a manufacturer of stainless steel sanitary valves, SIMPLE VALVES aims to arm its potential customers with information that would help them in making an informed decision.

Our sales representatives are ready to help, please feel free to email us at sales@simplevalves.com or submit your request directly in below form.

Leave A Comment