Sanitary pressure relief valves are used to regulate the pressure in plumbing systems and pumps, thereby preventing dangers and operation breakdown. They’re designed to be constantly and automatically available for these two conditions:

- Emergency conditions pressure build-up due to equipment failure, system upset, or malfunctioning.

- Normal conditions: pressure build-up as a result of daily system routines.

They feature stainless design and other hygiene and safety features that make them suitable for protecting equipment used in high-pressure food processing, biopharmaceutical, chemical, and personal care industries.

For example, you can spot them on the side of most water heaters. They’re referred to as water heater pressure relief valves used to keep the device from excess pressure build-up and overheating. That’s why your water heater doesn’t turn into a bomb when you heat water to high temperatures leading to a build-up of steam.

Operating Principles of Sanitary Pressure Relief Valves

Pressure relief valves simply function by opening when pressure build-up inside the system goes beyond some specified mark. When the valve opens, the fluid, liquid, moisture or steam escapes and the pressure inside the system lowers to an average level.

The spring-loaded pressure relief valve is the most common design and features the valve body, nozzle/inlet, pipes, bonnet, spring, disk, disk holder, and seat. When the conditions are normal/ balanced, the spring load maintains the disk on the nozzle and outflow remains prevented. When the inlet pressure later exceeds the spring force, the spring lets go of the disk and outflow is allowed. You can set the pressure at which the spring holds on, or let go of the disk by calibrating the spring load using some Pressure Nut.

Most pressure relief valves are designed to automatically open when the pressure gets high. And they usually close when the pressure returns to an average level. Normally closing helps to block flow so that the pressure doesn’t drop below the average level.

The spring keeps the valve closed and allows it to open only when the system experiences pressure build-up and closes once things are back to normal thus:

- Ensuring the safety of the people

- Guaranteeing the lifespan of the equipment

- Ensuring continuity of operation

The pressure relief valve, however, should not be confused with a back-pressure regulator. Here’re the differences:

- Pressure Relief Valve vs. Back-Pressure Regulator

A back-pressure regulator is used to maintain a steady flow of pressure inside a system. It is a part of the system and has sensors that enable it to stabilize the system in real-time.

A pressure relief valve, on the other hand, is a programmable valve that opens when a system needs to release excess pressure. It’s not a functioning part of the system but just a safety mechanism designed with the following features.

Technical Specifications of Sanitary Pressure Relief Valves

They are designed according to Pressure Vessel Code and Section VIII ANSI Code guidance that specifies the piping and corrosion resistance features for relief systems.

The steel body makes the pipe suitable for the high-pressure operations they’re intended to; polished steel-surface finishing, on the other hand, eliminates crevices that would otherwise lead to unhygienic operations.

To ensure smooth drainage and quick pressure-relieving, the discharge pipe are designed to slope from the outlet for smooth and faster discharge drainage when the valve opens up.

To be used in extreme temperature and high-pressure operations, the valves are mostly designed with EPDM sealing to withstand a maximum temperature of 120°C. Other reliable sealing material designs you can get include silicone or FPM Viton gaskets and seals.

You can pick pressure relief valves according to your desired working pressure ranges. Most pressure relief valves in the market fall into the spring-loaded 0-8 bar or 0-3 bar working pressure category.

For leakproof sealing to prevent pressure drops and leakages, the end connections can be a sanitary clamp, butt-weld, flange, or threaded.

Apart from relieving the pressure, the valve can also be used to allow for liquid flow when it’s partially opened for CIP. The actuator used to position the valve plug relative to the valve’s seat for partial opening of the valve can be pneumatic actuator or a quick release handle.

Are there Instances of Failure of Sanitary Pressure Relief Valves?

Though pressure relief valves have proved to be relatively reliable tools, there have been instances of overpressure — though very low — due to valve failures. Such instances happen when:

- Valves fail to open when required: a valve may fail to open or open at a higher pressure than the one set.

- Valves open when not required: a valve opens at a lower pressure than the one set, leaks or fails to reseat after opening.

However, aside from the above incidents, pressure relief valves are essential in preventing damages and equipment breakdown. They’re widely used in high-pressure systems and are available in a variety of configurations.

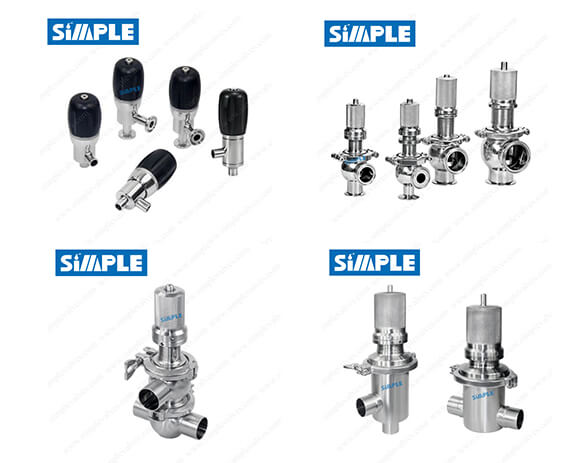

Other Designs of Pressure Sanitary Pressure Relief Valves

Apart from the Spring-loaded pressure relief valve discussed above, you can get the following designs too:

- Safety Valve: designed to pop open when the static inlet pressure builds up during high-steam operations.

- Relief Valve: gradually lifts open in proportion to how the pressure builds up in the system over the system opening pressure.

- Safety Relief Valve: rapidly pops open in proportion to the pressure build-up over the opening system pressure.

- Temperature-Actuated Relief Valve: actuated by temperature build-up in the inside or outside of the system.

- Power-Actuated Relief Valve: the actuator device gets power from an external energy source and relieves the pressure from the system.

In retrospect, most pressure relief valves are spring-loaded and allow calibration to set the pressure at which the valve opens or closes to regulate the pressure of a particular system, thereby ensuring safe and continuous operations. Pressure relief valves are simple to operate and maintain clean, therefore widely used in sanitary applications.

Our People Want to Help

As a manufacturer of stainless steel sanitary valves, SIMPLE VALVES aims to arm its potential customers with information that would help them in making an informed decision.

Our sales representatives are ready to help, please feel free to email us at sales@simplevalves.com or submit your request directly in below form.

Leave A Comment